What is a Thread Tap?

A thread tap is a cutting instrument used to form internal threads in a pre-drilled hole. This procedure, known as tapping, is essential for creating threads in bolts, screws, and other fasteners. Thread taps are often composed of high-speed steel, carbide, or other robust materials that can endure the demands of thread cutting. Tapping is often done on metals, polymers, and other materials that may accommodate a threaded insert.

The thread tap has cutting edges and grooves to remove material from the hole and create a precise thread pattern. It can be done manually or with the help of automated machines, depending on the application.

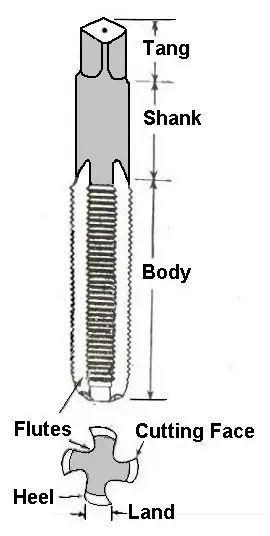

What are the Components of a Tap?

Understanding the components of a tap is crucial for choosing the right tool and using it effectively. A typical tap consists of the following。

Shank

This is the portion of the tap that slides into the chuck of a machine or hand tool. It is the tap’s non-cutting part, which may vary in length and form according on the tap’s design and intended usage.

Flutes

Flutes are the spiral grooves that span the whole length of the tap. These grooves have two functions: they provide room for the cut material to be removed and enable coolant or lubricant to flow through the tap during the threading operation. Flutes also assist in guiding the tap as it makes the threads.

Cutting Edges

These are the sharp edges of the tap that carry out the cutting operation. The cutting edges are often located on the outside margins of the flutes. As the tap spins, these edges scrape away material from the hole, creating the appropriate thread profile.

Point

The point of the tap is the tip of the tool, responsible for initiating the cutting action. Depending on the type of tap, the point may be pointed (for starting threads in blind holes) or flat (for through-hole applications).

Lead

The point of the tap is the tool’s tip that initiates the cutting motion. Depending on the tap, the tip may be sharp (for initiating threads in blind holes) or flat (for through-hole applications).

Neck

The neck is the part of the tap that tapers from the shank to the cutting edges. It enables the tap to penetrate the material with less friction and avoids binding during operation.

What Are The Types of Thread Taps?

Taps are classified into numerous categories, each of which is appropriate for a distinct threading operation, material type, and thread profile. Some of the most popular kinds of taps are。

Hand Taps

Hand taps are manual taps that are often employed in minor operations or to create threads in less demanding applications. They normally occur in threes: a taper tap, a second tap, and a bottom tap.

The taper tap has a more gradual thread cutting profile, the second tap is a middle-ground tool, and the bottoming tap is used to cut threads all the way to the bottom of the hole. Hand taps are utilized when accuracy and human control are critical, and they are often employed to make threads in tiny holes.

Machine Taps

Machine taps are intended for use with automated equipment including drilling machines, CNC machines, and tapping machines. These taps are intended for quicker and more accurate threading operations than hand taps. They are often employed in mass-production situations. Machine taps are available in a number of forms, including spiral flute taps, spiral point taps, and straight-flute taps, with each suited for a certain sort of thread cutting.

Spiral Flute Taps

Spiral flute taps have helical flutes that drive chips and cutting waste upward and out of the hole. These taps are great for tapping through-holes because they assist remove the chips more effectively, reducing blockage. Spiral flute taps are also often employed when dealing with materials that create long, stringy chips, such as aluminum. The spiral design improves the efficiency of the tapping operation and may extend the life of the tap.

Spiral Point Taps

Spiral point taps, sometimes known as gun taps, are meant to drive chips forward out of the hole rather than draw them back. This style of tap is ideal for through-hole applications where chips may be expelled fast. The spiral tips serve to push material outward, reducing clogging in the flute region. They are often utilized in automated or high-speed tapping applications because to their capacity to handle enormous amounts of chips.

Straight Flute Taps

Straight flute taps have straight grooves across the length of the tap, which may assist remove chips from the hole but are less effective than spiral flutes in certain situations. Straight flute taps are often utilized in blind holes or to tap materials that do not create a lot of chips. While they are effective for low to moderate-speed tapping, they are not suitable for high-volume or high-speed activities because they may rapidly get blocked.

Bottoming Taps

Bottoming taps are designed to cut threads all the way to the bottom of a hole. They are often utilized in situations requiring deep or blind holes with threads that reach as long as feasible. The bottoming tap’s tip is flat to avoid cutting material too forcefully at first, allowing it to perform well in deeper holes. These taps are perfect for applications that need a completely threaded hole.

Chasing Taps

Chasing taps are specialist taps that clean or pursue existing threads in previously tapped holes. They do not remove material in the same manner as cutting taps; instead, they clean up rough or damaged threads to ensure they match the needed requirements. Chasing taps are often used to repair broken threads or eliminate flaws after first tapping.

Pipe Taps

Pipe taps are especially intended to produce tapered threads in pipe fittings. These taps are utilized in applications that include plumbing or pipe systems, such as construction and oil and gas. Pipe tap threads are tapered, enabling pipes to fit securely when linked together.

How To Use a Tap for Threading?

Threading with a tap is a precise procedure that demands both the proper instruments and a thorough grasp of the technique. Here’s a basic tutorial on using a tap for threading.

Step 1: Select the Correct Tap

Before you begin, be sure you choose the right tap for your material, hole size, and thread requirements. Consider the material you’re dealing with, the required thread profile, and whether the hole is through or blind.

Step 2: Prepare the Hole

Drill the hole to be tapped to the right size. The hole size is critical because if it is too big or too tiny, the threading operation will fail or produce an erroneous thread. The drill size needed varies according on the thread type and tap being used. To find the proper hole size, use a drill chart or manufacturer’s instructions.

Step 3: Lubricate the Tap

Lubrication is vital for reducing friction and heat buildup during the tapping operation. Use the cutting oil or lubricant that was advised for your material. Proper lubrication increases the life of the tap and provides clean, precise threads.

Step 4: Insert the Tap and Begin Tapping

Insert the tap into the hole, keeping it straight and center. If you’re turning a hand tap, use strong but even pressure to keep the tap in the proper alignment. If you use a machine tap, be sure it functions at the proper speed and pressure.

Step 5: Back Out the Tap Occasionally

Backing out the tap on a regular basis is necessary to remove chips and dirt from the flutes. This keeps the tap from binding and creates a clean, accurate thread. For bigger holes or deeper threads, additional taps may be required to finish the threading procedure.

Step 6: Inspect the Threads

After tapping, check that the threads are homogeneous and correctly formed. Using a thread gauge, verify the pitch and fit of the threads. If required, tidy up or refine the threads with a chasing tap.

Tips for selecting the Right Thread Tap Type

Choosing the appropriate tap is determined by a variety of variables. Here are some important considerations.

Material

Taps must be designed for certain materials. For example, stronger materials like stainless steel may need taps manufactured of high-speed steel (HSS) or carbide, but softer materials like aluminum may be tapped with ordinary steel taps.

Hole Type

The sort of hole—through or blind—determines the type of tap to employ. Spiral flute taps are appropriate for through-holes, while bottoming taps are required for blind holes with full-thread depth.

Thread Type and Size

The tap option is determined by the kind of thread you are making (such as UNC, UNF, or metric threads). Make sure the tap you choose is appropriate for the thread size and pitch.

Speed and Efficiency

Machine taps are favored for mass manufacturing or high-speed operations because they can operate more quickly and correctly. Hand tapping, on the other hand, may be more appropriate for little, specific chores or one-time undertakings.

How To Get A Thread Tap Size with a Chart?

Refer to a tap size chart to identify the right tap size for an application. A tap chart shows the drill size needed for the thread size and pitch. Many manufacturers give these charts for easy reference to ensure the hole is drilled correctly before tapping.

Properly threaded holes need the right tap size. Tap sizes depend on hole size and thread type (Metric or Unified). The tap table below displays typical drill diameters for several tap types.

| Thread Size | Tap Drill Size (Metric) | Tap Drill Size (Imperial) |

|---|---|---|

| M2 x 0.4 | 1.6 mm | #56 (0.046 in) |

| M3 x 0.5 | 2.5 mm | #49 (0.070 in) |

| M4 x 0.7 | 3.3 mm | #36 (0.106 in) |

| M5 x 0.8 | 4.2 mm | #29 (0.136 in) |

| M6 x 1.0 | 5.0 mm | #22 (0.157 in) |

| M8 x 1.25 | 6.75 mm | #16 (0.177 in) |

| M10 x 1.5 | 8.5 mm | #12 (0.189 in) |

| 1/4”-20 UNC | 0.200 inches | #3 drill (0.200 in) |

| 5/16”-18 UNC | 0.242 inches | #2 drill (0.242 in) |

| 3/8”-16 UNC | 0.281 inches | #1 drill (0.281 in) |

Always consult a tap chart to determine the appropriate drill bit size and tap for your project.

Online Taps Caculator

For Unified Threads (UNC/UNF):

Tap Drill Size Calculator (UNC/UNF)

Conclusion

Thread taps are essential for accurate internal threading in various materials. Understanding the function and features of each tap type can help you choose the ideal one for your project. Using the proper tap type for metals, plastics, or other materials ensures quick and precise threading, boosting product quality and robustness.

FAQs

What is the difference between a hand tap and a machine tap?

Machine taps are for automated or high-speed threading, whereas hand taps are for human threading. Machine taps are quicker and more exact, while hand taps are better for minor projects.

Can I use the same tap for all materials?

No, materials need different taps. Aluminum may be tapped with conventional steel taps, whereas stainless steel requires high-speed steel or carbide taps.

How do I prevent a tap from breaking?

Make sure the hole is the right size, lubricate the tap, and avoid excessive force while tapping to avoid damaging it. usage the right tap for the material and usage.

What is the purpose of the flutes on a tap?

Tap flutes remove chips and dirt from holes when cutting threads. These guides assist guide the tap and enable lubrication while tapping.

Can taps be re-sharpened?

Yes, taps may be re-sharpened if they become dull, but the geometry must be accurate. Re-sharpening a tap poorly might affect the workpiece or thread quality.