What is hard coat anodising?

Hard Coat Anodising, also known as Type III Anodizing, is a cutting-edge electrochemical technique that improves the surface qualities of aluminum and other nonferrous metals. This method forms a thick and permanent coating of aluminium oxide, considerably increasing the material’s hardness, wear resistance, and corrosion resistance.

What is the hard coat anodising process?

The Hardcoat anodising method is a specialized electrical treatment that makes an oxide layer that is thick, strong, and resistant to rust on aluminum and its alloys. The surface qualities of the material are greatly improved by this process, which makes it ideal for demanding uses in many industries.

Step 1: Surface preparation:

An alkaline solution is used to completely clean the aluminum part, removing impurities such as grease and grime. This step is crucial to achieving a high-quality anodized finish.

The item may be acid etched to remove any naturally occurring oxide layers, resulting in a homogeneous surface that improves adherence for the anodized coating.

Step 2: Anodising Bath

The cleaned aluminum portion is immersed in a sulfuric acid electrolyte bath, which is normally kept at low temperatures (28°F to 32°F). This controlled atmosphere is required to get the desirable qualities of the anodized layer.

Step 3: Applying Electric Current

An electric current flows through the bath, with the aluminium serving as the anode. This starts an electrochemical reaction that results in a thick layer of aluminum oxide on the surface. The voltage usually starts around 25 volts and can grow to 120 volts as the anodic layer thickens.

Step 4: Controlled Conditions

Hardcoat anodising requires certain temperature and current density conditions (often 24 to 40 amps per square foot). These factors are critical for creating a thicker, denser, and less porous oxide coating than traditional anodising methods.

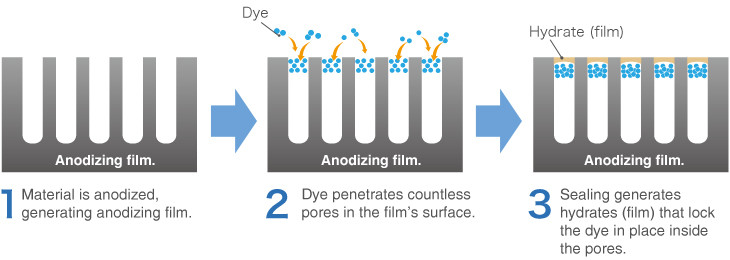

Step 5: Sealing

When the desired thickness of the anodised layer is reached (13 to 150 micrometres), the item is taken from the bath and sealed to close any gaps in the oxide layer. This sealing technique frequently includes immersion in boiling deionised water or a chemical sealing solution, which improves corrosion resistance and color retention if colouring is needed.

Step 6: Final Rinsing and Drying

After sealing, the part is rinsed again to eliminate any residual chemicals before being dried and ready for use or further processing.

What characteristics and features of ard coat anodising?

Hard anodising enhances the surface properties of aluminium and its alloys by creating a thick, durable oxide layer. This treatment provides several distinctive characteristics and features that make it suitable for various industrial applications.

Thickness

Hard anodising produces an anodised coating that is typically 13 to 150 micrometres (0.0005″ to 0.006″) thicker than other forms of anodising. In comparison, Type II anodising typically has a thickness of 5 to 25 micrometres (0.0002″ to 0.001″. The greater thickness improves corrosion and wear resistance.

Hardness and Wear Resistance

Hard anodised coatings often have a Vickers Hardness (HV) of 400 to 600, making them significantly harder than normal anodised layers with an HV of 200 to 400. This hardness translates into outstanding wear resistance—hard anodised surfaces can be almost ten times more wear resistant than standard anodised aluminium.

Corrosion Resistance

Hard coat anodising considerably enhances corrosion resistance, with coatings often lasting over 1000 hours in a salt spray test (ASTM B117). The thicker oxide layer successfully protects the aluminium underneath from oxidation and environmental deterioration.

Electrical Properties

The oxide layer generated during hard anodising has good electrical insulation qualities, ranging in resistivity from 10111011 to 10151015 ohms. As a result, hard anodised aluminium is appropriate for applications that require nonconductive surfaces.

Heat Resistance

Due to their inert nature, hard anodised coatings can tolerate short exposures to temperatures of up to 2000 degrees Celsius. This feature is particularly useful in high-temperature situations.

Thermal Properties

Hard coat anodized surfaces have poor thermal conductivity but high thermal emissivity, making them suitable for heat dissipation in engineering applications such as heat sinks.

Aesthetic Options

Hard anodized aluminum can have different colors depending on the metal and the thickness of the covering. Usually, the colors range from dark gray to bronze-gray. These surfaces can also be dyed black to make them look better while still keeping their protective properties.

Surface Roughness

Due to the heavy oxide layer, the procedure may provide a rougher surface roughness than other anodising methods, necessitating additional finishing processes for applications that require smooth surfaces.

What’s the difference between hard coat anodising and regular anodising for aluminium?

Hard coat anodising and regular anodising (also known as standard anodising or Type II anodising) are two separate procedures used to improve the surface qualities of aluminum. The following is a comparison that highlights the significant variations in procedure, properties, and applications.

Process and Conditions

- Hard coat anodising is carried out under more regulated conditions, with lower temperatures and higher current densities. This results in a thicker, denser oxide layer, which increases durability.

- Regular anodising, on the other hand, occurs at room temperature with lower current densities, resulting in a thinner and softer anodised coating.

Oxide Layer Characteristics

- Hard coat anodising produces a substantially thicker oxide coating (up to 150 micrometres), which provides greater wear resistance and corrosion protection. The hardness of this layer can range from 400 to 600 HV.

- Regular anodising creates a thinner oxide layer (5-25 micrometres) that is softer and mostly decorative in nature.

Performance Properties

- Hard coat anodized surfaces are extremely wear resistant, making them ideal for applications involving intense friction or abrasion. They can endure rigorous abrasion resistance testing standards like ASTM D4060.

- Regular anodized surfaces have reasonable wear resistance but are unsuitable for high-stress applications.

Applications

- Hard coat anodising is widely utilized in areas requiring high durability, such as aircraft components, military equipment, medical devices, and automotive parts.

- Regular anodising is more typically used for decorative coatings on consumer goods and components that do not require high durability.

What are the benefits and limitations of hardcoat anodising?

Hard coat anodising has various advantages for improving the performance and lifespan of aluminum components. The following are the key benefits of this method, as well as some limits to consider.

Benefits of Hard Coat Anodising

Enhanced Hardness

Hard coat anodising greatly increases the surface hardness of aluminium, resulting in Rockwell C hardness ratings ranging from 50 to 70. This increased hardness provides improved resistance to wear, abrasion, and scratching, making it perfect for high-stress applications.ns.

Improved Corrosion Resistance

The thick anodised oxide coating serves as a protective barrier against external conditions, resulting in exceptional corrosion resistance. Hard coat anodized aluminium can withstand salt spray testing for over 2000 hours (ASTM B117), making it ideal for severe settings.

Increased Durability

The thick oxide coating considerably increases the durability of hard coat anodized components. This endurance extends the life of the parts, allowing them to withstand repeated use without losing structural integrity.

Exceptional Wear Resistance

The dense anodic coating formed during hard coat anodising has excellent wear resistance, making it ideal for components subjected to mechanical stress and friction.

Dielectric Properties

The oxide layer is non-conductive and has a high dielectric strength, with breakdown voltages ranging from 600 to 1000 volts per mil. This makes hard coat anodising ideal for electrical insulation applications.

Enhanced Heat Dissipation

Because of its high emissivity and absorptivity, hard coat anodized aluminum can improve heat dissipation by up to 30% when compared to raw aluminium.

Limitations of Hard Coat Anodising

Limited Colour Options

Unlike ordinary anodising procedures, which give a wide range of brilliant colours, hard coat anodising often produces darker finishes (dark grey or black), which may not meet all aesthetic criteria.

Thickness Limitations

The larger oxide layer might have an impact on dimensional tolerances, making it unsuitable for applications needing precise specifications.

Surface Roughness

Hard coat anodizing may yield a rougher surface roughness than other anodising procedures, necessitating additional finishing processes for applications that require smooth surfaces.

Brittleness

The hard coating can be relatively brittle, making it unsuitable for components subjected to strong impacts or bending stresses.

What is the standard requirement for hard coat anodising?

Several industry standards and criteria control hard coat anodising, ensuring the quality and performance of the coatings. The following are the major standards and quality testing techniques for hard coat anodising.

- MIL-A-8625: This is the primary military specification for anodizing aluminum, outlining the specifications for hard coat anodising (Type III). It describes process controls, coating thicknesses, and quality assurance measures.

- AMS 2469: The Aerospace Material Specification (AMS) specifies the specifications for hard anodic coatings on aluminum alloys, with a focus on performance and durability.

- ASTM B580: This standard specifies the requirements for hard coat anodizing aluminum for architectural purposes, including corrosion resistance and coating integrity.

- ISO 10074: This is an international standard that outlines the requirements for hard anodising, with a focus on quality control and testing techniques.

- MIL-A-63576: This specification includes provisions for PTFE sealing of hard anodized surfaces, which improves wear resistance and lubricity.

- AMS 2482: This specification, like MIL-A-63576, addresses PTFE sealing in hard coat anodized applications to improve performance characteristics.

How many types of quality inspections for hard coat anodising?

Quality testing is essential to ensuring that hardcoat anodised surfaces fulfill the required performance parameters.

- Taber Abrasion Test (ASTM D4060): This measures wear resistance by subjecting the anodized surface to rotational abrasion under a specified force. Weight loss is measured to determine durability.

- Dye Spot Test (ASTM B136): This evaluates the sealing process’s quality by determining if a dyed sample retains color while immersed in a hot solution, suggesting that the oxide layer has been well sealed.

- Admittance Test (MIL-A-8625): A non-destructive test that determines the electrical admittance of the anodized layer, which is proportional to thickness and sealing quality.

- Salt Spray Test (ASTM B117): This test evaluates corrosion resistance by exposing samples to a salty environment for lengthy periods of time; hard coat anodized aluminum normally withstands more than 2000 hours in this test.

- The HCl Bubble: This includes immersing the anodised coating in a weak hydrochloric acid solution to look for visual indicators of coating failure caused by hydrogen bubble formation.

- Extreme Alkaline Resistance Test: This test evaluates the anodised layer’s performance in high pH values to ensure longevity in hostile chemical environments.

What are the Applications of Hard Coat Anodising?

Aerospace Industry

Hard coat anodising benefits structural parts, gears, and hydraulic systems by allowing them to tolerate extreme operational conditions, increasing longevity and corrosion resistance.

Military and Defence

Hard coat anodising is essential for guns, vehicles, and other defense equipment because it provides the necessary protection against hostile environments and hard use.

Medical Devices

Surgical tools and medical devices require surfaces that are long-lasting, non-contaminating, and able to resist repeated sterilization operations. These requirements are effectively met by hardcoat anodising.

Automotive Components

Hard coat anodising is used to preserve engine parts, brake systems, and suspension components against wear and corrosion, increasing vehicle reliability and lifespan.

Robotics

In robotics, hard coat anodized surfaces protect delicate components from wear and tear, assuring long-term performance.

What factors will affect the hard coat anodising?

Alloy Composition

The anodised layer’s qualities depend on the aluminum alloy. Different alloys react differently to anodising, changing pore size and depth, which affect oxide layer hardness and endurance. Purer aluminium alloys Anodize more uniformly and harder than those with more alloying components.

Surface Quality

High-quality anodising depends on the aluminium part’s original surface state. Uneven anodisation due to scratches, dents, or impurities might reduce oxide layer thickness or adherence. The surface must be thoroughly cleaned and prepared for optimal anodised coating adhesion and performance.

Anodising Parameters

Voltage, current density, temperature, and acid concentration determine hard coat anodizing quality. Different current densities affect coating complexity and density, whereas higher voltages and lower temperatures yield thicker and tougher oxide layers. Optimal coating properties need careful management and monitoring of these factors.

Conclusion

Finally, hard coat anodizing improves hardness and corrosion resistance, making it suited for demanding applications. It offers limited color possibilities and surface roughness, but meticulous alloy composition and production conditions provide high-quality finishes that match industrial requirements.