What Are Engineering Plastics?

Engineering plastics are a group of plastic materials. They demonstrate superior mechanical, thermal, chemical, and electrical properties compared to standard or commodity plastics. Engineering plastics are specifically designed to withstand more demanding conditions, often substituting metals and other traditional materials. They’re used in a wide range of applications. Engineering plastics are different from the common plastics you use to make packaging and disposable items. You engineer engineering plastics for long-term performance and reliability.

Why Choose Engineering Plastics?

Engineering plastics are awesome because they balance performance and cost like nothing else. Here’s why:

- Light. They weigh a fraction of metals, saving fuel in vehicles and making them much easier to handle in all sorts of situations. It’s how we build a sustainable world.

- Formable. You can shape them into very complex forms, enabling designs in automotive and electrical industries that were never possible before.

- Tough! They withstand the kind of abuse and loads that would drive most of us to the “down for maintenance” department, including strength under wear, impact, and nasty chemicals.

- Cost-effective. Even though we thought they were expensive to buy, they’re often easier and less expensive to process, will perform longer than metal in many applications, and cost less in the long run.

Key Properties of Engineering Plastics

If you’re still on the fence, the benefits listed below ought to be enough to offset a moderate amount of hand-wringing:

Strong

How well a material withstands deformation or breaking under load is one of the things we consider when we talk about strength. Because engineering plastics like polycarbonate and nylon have such great tensile, bending, and impact strengths, we get excited about them.

Heat-resistant

How well a particular material retains its properties at elevated temperatures is something we need to know. Engineering plastics like PEEK and PPS don’t melt when things get hot, making them more than suitable.

Chemically stable

They’re resistant to harsh chemicals, including acid and most solvents.

Electrically gifted

Some of them are great insulators and can provide dielectric strength, which makes them ideal for use in the electrical world. We can make others conductive or electro-static dissipative, too.

Special performance

Some engineering plastics have particular assets, like flame retardance, wear resistance, and dimensional stability, that make them great for particular things.

The Types of Engineering Plastics

Engineering plastics encompass a broad and varied world. Here are a few of the most commonly used types.

High-Performance Engineering Plastics

Polyamide (PA Nylon)

Known for its excellent strength wear resistance and good chemical resistance. The automotive industry and gear manufacturers love this hard-working plastic. A study by the American Chemical Society touted how strong Nylon 6,6’s tensile strength makes it suitable as a metal replacement in certain structural engineering applications.

Polycarbonate (PC)

This nearly transparent bulletproof plastic is known for its high impact resistance and heat resistance. It’s great for lenses safety glasses and electronic components. A report by the National Institutes of Health highlighted how medical equipment manufacturers use polycarbonate due to its high strength and biocompatibility.

Polyoxymethylene (POM)

Also known as acetal this engineering plastic is valued for its high stiffness low friction and wear resistance. It’s used a lot for gears bearings and other moving parts. It’s often the choice for components where tight tolerance and repetitive motion resistance are needed.

Polyetheretherketone (PEEK)

This is a high-performance thermoplastic with exceptional thermal stability chemical resistance and mechanical strength. Aerospace companies medical implant manufacturers and the oil and gas business use PEEK in their products because of its ability to survive brutal conditions.

Other Common Engineering Plastics

Acrylonitrile Butadiene Styrene (ABS)

You can do some great stuff with this plastic because it has good impact resistance and machinability. It’s ideal for lots of automotive applications electronic housings and consumer goods.

High-Density Polyethylene (HDPE)

This plastic is known for its high strength-to-density ratio. It is also chemical resistant and recyclable. This makes it a good material for things like piping containers and even automotive fuel tanks. *

Polyethylene Terephthalate (PET)

With this thermoplastic you get high strength dimensional stability and really good barrier properties. They use it to make bottles packaging and textiles out of this material. *

Polymethyl Methacrylate (PMMA / Acrylic)

If you want a clear plastic with high transparency good impact resistance and weatherability use this plastic. It’s ideal for all sorts of stuff including lenses signage and displays. *

Polyphenylene Sulfide (PPS)

Good looking stuff right? This plastic has excellent chemical and thermal resistance and is used in lots of automotive electrical and industrial stuff as a replacement for metal parts. *

Polyphenylene oxide (PPO)

This material is known for its high dimensional stability good electrical insulation and resistance to water absorption. This is a great plastic for use in electrical enclosures and automotive components.

Polybutylene Terephthalate (PBT)

Use this stuff when you need excellent mechanical properties and chemical resistance as well as dimensional stability. Typically you will find it in electrical connectors automotive components and housings.

Liquid Crystal Polymer (LCP)

Known for its high strength dimensional stability and heat resistance. You find this plastic in lots of electronics medical and aerospace kind of stuff.

Cyclic Olefin Copolymer (COC)

When clarity biocompatibility or good barrier properties matter this plastic knocks it out of the park. You will find it in packaging optical components and medical applications.

Specialty Engineering Plastics

Polyetherimide (PEI/Ultem)

Perfect for aerospace, automotive and medical devices. Its high strength, thermal resistance, and flame retardancy make it a versatile choice across the broad market.

Polyamide-imide (PAI/Torlon®)

This material has characteristics offering widespread suitability in aerospace, automotive, and simply demanding applications due to its very high strength, stiffness, and thermal resistance.

Polytetrafluoroethylene (PTFE/Teflon®)

Known for its low friction, nonstick features, chemical inertness, and high thermal resistance, PTFE is everywhere, from Teflon® coatings on cooking pans to seals throughout the world.

Engineering plastics are used in various industries

Automotive

Automotive application is a major market for engineering plastics, which includes interior parts like dashboards, consoles, and exterior parts like bumpers, and body panels, as well as parts critical under the hood. It helps reducing vehicle weight, which improves fuel efficiency and safety.

Electronics and Electrical

Engineering plastics are extensively used in electronic housings, connectors, terminal blocks, circuit boards, insulation materials, and other electronic devices, offering insulation, durability, electrical insulation, and protection to electronic devices.

Medical devices

Biocompatibility, sterilizability, and chemical resistance properties make them essential for medical equipment housings, surgical instruments, implants, and diagnostic tools.

Aerospace

High strength-to-weight ratio combined with resistance to extreme temperatures and chemicals make them attractive for aircraft interiors, engine components, and spacecraft.

Industrial

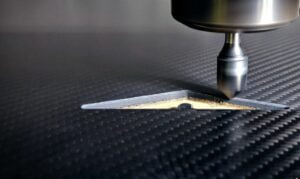

Industrial applications include gears, bearings, pipes, pumps, valves, and 3D printing materials. Versatile materials are engineered for performance in heavy-duty machinery.

Selecting the Right Engineering Plastic

When it comes to selecting the right engineering plastic, there are several factors you need to consider. Here’s a roundup:

- Application Environment:Make sure you understand the operating temperature, any exposure to chemicals, humidity levels, and mechanical stresses your component(s) will experience.

- Performance Requirements:Be sure you know the mechanical, thermal, chemical, and electrical properties you need for your application.

- Cost and Processability:Make sure you balance material performance with cost effectiveness and the cost to make your end product.

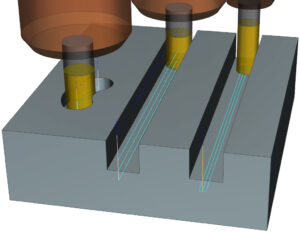

- Processing Methods:This includes things like injection molding, extrusion, and blow molding. Many of our customers make parts with each of these processes, which we’ll touch on in a moment.

- Injection Molding:This is the best thing to do if you’re going to make high volumes of complex parts with really high precision. You will pay for the precision and accuracy you will get with the parts; and

- Extrusion:This is best done if you need to make continuous lengths of a profile, make film, or make a pipe, for example.

Key Differences Between Engineering Plastics and Commodity Plastics

Engineering plastics and commodity plastics are both thermoplastics, yet they have different properties and uses. By knowing the differences, you can choose the right materials for your applications.

Mechanical and Thermal Properties

Between engineering plastics and commodity plastics, engineering plastics are stronger, resist heat better, and have more consistent dimensions. They can hold up under tough mechanical and environmental conditions. That’s why they’re in cars and machines.

Commodity plastics aren’t as strong. They work for things that get made in lots and don’t need to be especially good, like boxes and spoons. That’s why they’re cheaper.

Cost

Sometimes engineering plastics cost more than commodity plastics because they’re more special. When you pay more for a plastic, that’s ok when you need the thing you’re making to last a long time and be good.

Commodity plastics are usually cheap. That’s good when you have to make millions of things that don’t need to be great, like garbage bags.

Applications

The most common place you find engineering plastics is where people make things that have to be super-good. People use them in cars, airplanes, heaters, and factories. The fact that you can use them instead of metal is good since they’re light and don’t wear out, and chemicals won’t hurt them.

You usually see commodity plastics when people make things that don’t have to be really good. They work for things you use for a little bit and then throw away.

Chemical Resistance

All good plastics can stand up to chemicals. A lot of engineering plastics can resist chemicals that would mess up other plastics. People use them to make tanks to store nasty stuff.

Commodity plastics can handle some chemicals, but they don’t do as well when chemicals are really nasty.

Performance Characteristics

| Feature | Engineering Plastics | Commodity Plastics |

|---|---|---|

| Mechanical Strength | High | Moderate |

| Heat Resistance | Excellent | Limited |

| Chemical Resistance | High | Variable |

| Cost | Higher | Lower |

| Typical Applications | Automotive parts, industrial machinery | Packaging, disposable items |

Frequently Asked Questions about Engineering Plastics

What are some differences between engineering plastics and commodity plastics?

Engineering plastics have better mechanical, thermal, and chemical properties compared to commodity plastics you see used for packaging and disposable items.

How do I select which engineering plastic is right for my application?

Think about the environment, performance, cost, and processing for your application. Also, consult with experts.

How do the costs of engineering plastics compare?

Typically, engineering plastics will be more expensive upfront compared to commodity plastics. However, the longevity and performance can make them cost-effective.

Can you recycle engineering plastics?

Most engineering plastics are recyclable, but it depends on the material and its intended application.

Conclusion

Engineering plastics are versatile and unsung heroes of modern innovation. These polymers provide solutions to complex technical problems in various industries. They are cost-effective and have good mechanical properties that allow engineers to design anything. If you want to change the world, you should learn about engineering plastics today.