The importance of CNC machining parts in various industries.

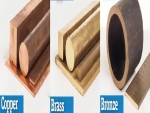

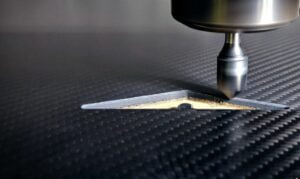

CNC machining part are parts and components that are produced through the process of computer numerical control (CNC) machining. This process involves the use of specialized machines, called CNC machines, that are programmed to cut and shape materials with high precision and accuracy.

CNC machining is an essential process in many industries due to its ability to produce highly accurate and complex parts with a high degree of precision and repeatability. CNC machining components are used in a wide range of industries, including automotive, aerospace, medical, consumer goods, construction, and more. These products are used in everything from car engines and aircraft parts to medical implants and consumer electronics. The importance of CNC machining lies in its ability to produce high-quality products that meet strict industry standards and specifications.

CNC machined parts in the automotive industry

Engine parts: CNC machined engine parts, such as cylinder heads, camshafts, and crankshafts, are crucial components in the functioning of an engine. These parts must be precise in order to ensure the smooth operation of the engine. CNC machining allows for the production of these parts with a high level of accuracy and repeatability, ensuring that they meet the strict standards required for use in the automotive industry.

Transmission components: Transmission components, such as gears, drive shafts, and bearings, are critical to the operation of a vehicle’s transmission system. CNC machining allows for the production of these components with a high level of precision, ensuring that they function smoothly and efficiently.

Exterior body panels: The exterior body panels of a car must be precisely shaped and fitted in order to give the vehicle a smooth, streamlined appearance. CNC machining allows for the production of these panels with a high level of accuracy, ensuring that they fit perfectly and contribute to the overall appearance of the vehicle.

Wheel hubs: Wheel hubs are important components in the suspension system of a vehicle. CNC machined wheel hubs are precise and durable, ensuring that they can withstand the rigors of driving and provide a smooth ride for the vehicle.

CNC machining aerospace parts

Fuel system components: The fuel system of an aircraft is a critical component that must be precise and reliable in order to ensure the safe operation of the aircraft. CNC machined fuel system components, such as fuel pumps and fuel lines, are produced with a high level of accuracy and precision, ensuring that they function correctly and safely.

Landing gear parts: The landing gear of an aircraft must be able to withstand the stresses of landing and takeoff and must be precise in order to ensure a smooth landing. CNC machined landing gear parts, such as wheels and struts, are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions.

Engine components: The engine of an aircraft is a critical component that must be precise and reliable in order to ensure the safe operation of the aircraft. CNC machined engine components, such as turbine blades and fan blades, are produced with a high level of accuracy and precision, ensuring that they function correctly and safely.

Flight control surfaces: Flight control surfaces, such as flaps and ailerons, are critical components that are used to control the movement of an aircraft in flight. CNC machined flight control surfaces are precise and durable, ensuring that they are able to perform their critical functions with a high level of accuracy and reliability.

CNC machine parts in the medical industry

Orthopedic implants: Orthopedic implants, such as hip and knee replacements, are used to repair or replace damaged or diseased bones. CNC machined orthopedic implants are produced with a high level of precision and accuracy, ensuring that they fit properly and function correctly.

Surgical instruments: Surgical instruments, such as scalpels and forceps, must be precise in order to ensure the success of a surgical procedure. CNC machined surgical instruments are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Dental implants: Dental implants, such as crowns and bridges, are used to replace missing teeth or to support dental prosthetics. CNC machined dental implants are produced with a high level of precision and accuracy, ensuring that they fit properly and function correctly.

Pacemaker components: Pacemaker components, such as electrodes and leads, must be precise and reliable in order to ensure the proper functioning of a pacemaker. CNC machined pacemaker components are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

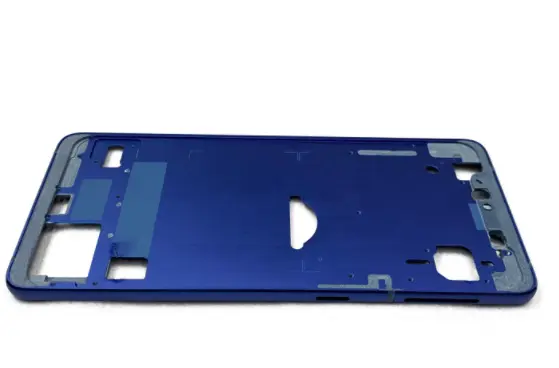

CNC machining parts in the consumer goods industry

Smartphone parts: Smartphones contain a wide variety of CNC machined parts, including circuit boards, connectors, and camera modules. These fast cnc machining parts must be precise in order to ensure the proper functioning of the smartphone. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Appliance components: Appliances, such as washing machines and refrigerators, contain a wide variety of OEM CNC machined parts, including gears, bearings, and control panels. These parts must be precise in order to ensure the proper functioning of the appliance. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Toys: CNC machining is often used to produce the intricate and precise parts used in the production of high-quality toys. CNC machined toy parts are produced with a high level of accuracy and precision, ensuring that they are able to withstand the rigors of play and provide a high level of enjoyment for children.

Sporting goods: CNC machining is used to produce the precision parts used in the production of high-quality sporting goods, such as golf clubs, skis, and snowboards. CNC machined sporting goods parts are produced with a high level of accuracy and precision, ensuring that they are able to withstand the rigors of use and provide a high level of performance for athletes.

Custom CNC machining parts in the construction industry

teel beams: Steel beams are a critical component in the construction of buildings and bridges. CNC machined steel beams are produced with a high level of accuracy and precision, ensuring that they are able to withstand the stresses of construction and provide structural support.

Concrete forms: Concrete forms are used to shape and mold concrete during the construction process. CNC machined concrete forms are produced with a high level of accuracy and precision, ensuring that they are able to provide a smooth and consistent finish to concrete surfaces.

Pipe fittings: Pipe fittings, such as elbows and couplings, are used to connect pipes and piping systems in the construction industry. CNC machined pipe fittings are produced with a high level of accuracy and precision, ensuring that they are able to fit together smoothly and provide a reliable connection.

Structural support parts: Structural support parts, such as braces and beams, are critical components in the construction of buildings and other structures. CNC machined structural support parts are produced with a high level of accuracy and precision, ensuring that they are able to withstand the stresses of construction and provide the necessary support for a structure.

CNC machining parts in the renewable energy industry

Wind turbine parts: Wind turbines contain a wide variety of CNC machined parts, including gears, bearings, and blades. These parts must be precise in order to ensure the smooth and efficient operation of the wind turbine. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Solar panel components: Solar panels contain a variety of CNC machined parts, including connectors, wiring, and mounting brackets. These parts must be precise in order to ensure the proper functioning of the solar panel. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Hydroelectric dam components: Hydroelectric dams contain a wide variety of CNC machined parts, including turbines, generators, and control systems. These parts must be precise in order to ensure the efficient and safe operation of the dam. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Geothermal power plant parts: Geothermal power plants contain a variety of CNC machined parts, including pumps, heat exchangers, and control systems. These parts must be precise in order to ensure the efficient and safe operation of the power plant. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

CNC machining parts in the food and beverage industry

Brewery equipment: Brewery equipment, such as fermenters and bottling machines, contains a wide variety of CNC machined parts, including gears, bearings, and control systems. These parts must be precise in order to ensure the efficient and safe operation of the equipment. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Food processing machinery: Food processing machineries, such as grinders and mixers, contains a wide variety of CNC machined parts, including gears, bearings, and control systems. These parts must be precise in order to ensure the efficient and safe operation of the machinery. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Restaurant kitchen equipment: Restaurant kitchen equipment, such as ovens and fryers, contains a wide variety of CNC machined parts, including gears, bearings, and control systems. These parts must be precise in order to ensure the efficient and safe operation of the equipment. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Packaging machinery: Packaging machinery, such as filling and sealing machines, contains a wide variety of CNC machined parts, including gears, bearings, and control systems. These parts must be precise in order to ensure the efficient and safe operation of the machinery. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

CNC machining parts in the oil and gas industry

Drill bits: Drill bits are critical components in the drilling process and must be precise in order to ensure the efficient and safe operation of the drilling equipment. CNC machined drill bits are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Pump parts: Pump parts, such as impellers and seals, must be precise in order to ensure the efficient and safe operation of pumping equipment. CNC machined pump parts are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Valve components: Valve components, such as stems and seats, must be precise in order to ensure the proper functioning of valves. CNC machined valve components are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Offshore platform equipment: Offshore platforms contain a variety of CNC machined parts, including control systems, pumps, and generators. These parts must be precise in order to ensure the efficient and safe operation of the platform. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

CNC machining parts in the electrical and electronics industry

Computer components: Computer components, such as processors and memory modules, contain a wide variety of CNC machined parts, including connectors, wiring, and control systems. These parts must be precise in order to ensure the proper functioning of the computer. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Electrical connectors: Electrical connectors, such as plugs and sockets, must be precise in order to ensure a reliable connection between electrical components. CNC machined electrical connectors are produced with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Circuit boards: Circuit boards contain a wide variety of CNC machined parts, including connectors, wiring, and control systems. These parts must be precise in order to ensure the proper functioning of the circuit board. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

Electronic parts and components: Electronic parts and components, such as sensors and switches, contain a wide variety of CNC machined parts, including connectors, wiring, and control systems. These cnc custom parts parts must be precise in order to ensure the proper functioning of the electronic component. CNC machining allows for the production of these parts with a high level of accuracy and precision, ensuring that they are able to perform their critical functions effectively.

CNC machining technology is constantly evolving, with new machines and techniques being developed all the time. These advancements will continue to improve the precision and efficiency of CNC machining, making it even more important in the manufacturing industry.

Thank you for reading our blog post on the topic of CNC machining parts. If you are in need of high-quality, precision on demand CNC machined parts for your industry, we invite you to contact us for more information. Our team of experienced machinists and engineers are ready to work with you to produce the parts you need to meet your specific requirements. Contact us today to learn more about how our CNC machining services can benefit your business.