What is Metal Additive Manufacturing?

Metal additive manufacturing, alternatively known as metal 3D printing, is a high-tech manufacturing method in which objects are produced by adding successive layers of material. The approach utilizes an energy source, for example, a laser or electron beam, to meld the metal powder or wire form together, forming a solid object. Consequently, this technique allows for the development of complex designs that cannot be achieved or are challenging to achieve with traditional manufacturing processes.

Metal additive manufacturing offers several advantages, including unmatched design freedom and the use of different metals. This has made it indispensable to the growth of the manufacturing industry, helping improve efficiencies, reduce waste, lower emissions, and increase production rates of more substantial, lighter parts. Aerospace, automotive, medical, and consumer goods have been identified as the primary beneficiaries of this technology.

Methods in Metal Additive Manufacturing

Powder Bed Methods

The powder bed method refers to when a thin layer of metal powder is spread over the surface of a bed. The thin layers then undergo selective melts and fuses from high-energy sources like lasers or electron emanations to form the desired item. It affords an exceptional ability to generate complex geometries with precision.

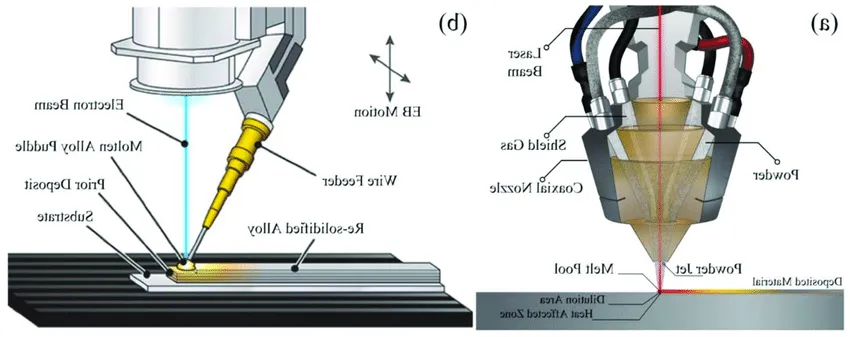

Directed Energy Deposition (DED)

In directed energy deposition, the material is melted by a heater while being deposited through a nozzle simultaneously. This process builds up layers to produce a solid object. DED is helpful in various industries because it can repair existing parts and add materials.

Metal Binder Jetting

Metal binder jetting utilizes liquid binders dispensed on top of successive layers of powdered metal, thus as glue between these particles. The resultant object requires further treatment, usually sintering or infiltration processes, to make it more robust/harder than before, though still retaining its shape without deformation. This method is helpful for many applications, especially those involving mass production, where complex parts are needed without raising temperatures too much.

Comparison of Different Metal Additive Manufacturing Methods

Powder Bed Methods

Advantages

Powder bed methods are the best methods for building complex shapes. This method is highly accurate and uses only the necessary powder thus saving on wastage. It can be modified to suit individualized products hence applicable across diverse metals and alloys.

Disadvantages

Expensive raw materials used in the procedures make it costly to purchase all the essential tools required. It has limited speed in addition to possible volume constraints during production. Surface treatments may require extra finishing after processing, also there are strict safety guidelines when working with metal powders.

Binder Jetting

Advantages

Supports are only sometimes needed in binder jetting, which reduces waste and post-processing costs. It recycles up to 99% of loose powder, enabling complex designs without increasing costs. Multiple parts can be made in one print, saving time and reducing cost.

Disadvantages

However, binder jetting requires additional equipment for post-processing, with most post-print processes being manual, although automation is underway. Besides, the cost of binder jetting machines is higher than that of many conventional manufacturing methods.

Direct Energy Deposition (DED)

Advantages

DED has a faster build rate than other metal AM technologies and creates dense parts with less waste material. It can produce significant components and work with different materials.

Disadvantages

On the downside, DED has low build resolution, which results in rough surface finishes. Machines are quite expensive, and no support structures are allowed in this process, meaning certain design features cannot be implemented.

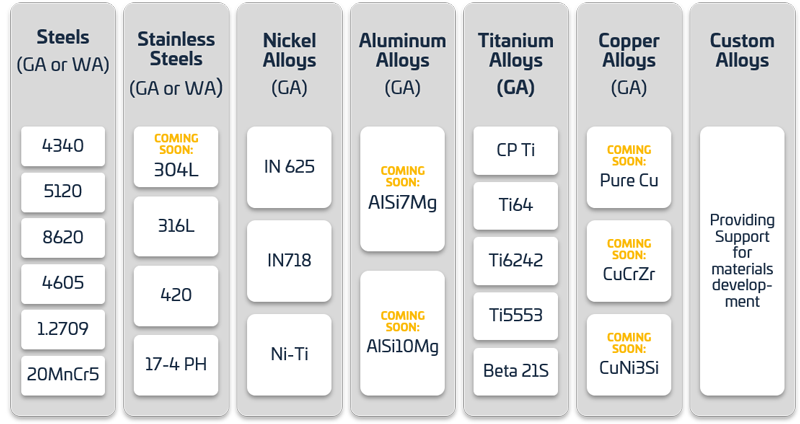

Metal Additive Manufacturing Materials

Common Metal Powders

The choice of material in metal additive manufacturing significantly affects the properties of the final product. Common materials include:

- Titanium and Titanium Alloys

High strength, corrosion resistance, and biocompatibility, ideal for aerospace, automotive, and medical uses.

- Stainless Steel

Balance of strength, corrosion resistance, and affordability.

- Aluminum and Aluminum Alloys

Lightweight with good conductivity.

- Nickel-Based Super Alloys

Superior heat and corrosion resistance for high-temperature applications.

- Cobalt-Chrome Alloys

High strength and biocompatibility, often used in medical applications.

- Precious Metals

They are used in jewelry for aesthetic qualities and corrosion resistance.

- Tool Steels

High hardness and wear resistance, ideal for creating molds and cutting tools.

Precious Metals in Additive Manufacturing

Precious metals such as gold, silver, platinum, and ruthenium are used in additive manufacturing for various applications:

- Silver

Electrical contacts and high-capacity batteries due to their high conductivity.

- Gold

Dentistry, medicine, and electronics for their malleability and resistance to tarnishing.

- Platinum

Jewelry, surgical tools, and laboratory utensils for their density and resistance to air and water.

- Ruthenium

Electronics and chemical industries for its resistance to acids and tarnishing.

Industry Applications of Metal Additive Manufacturing

Transform your production with Metal Additive Manufacturing. Cut costs, innovate faster, and achieve unparalleled precision.

Aerospace Industry

The aerospace industry was among the first to adopt metal additive manufacturing because it needed light and durable materials. This technology optimizes engine components, turbine blades, and fuel systems. Creating complex shapes without internal flaws has dramatically enhanced aerospace parts’ performance and functionality, leading to lighter aircraft and reduced fuel consumption.

Automotive Industry

Metal additive manufacturing is used in the automotive industry for metal prototyping, custom parts, and tooling. Auto manufacturers can use this innovation to develop new designs that they can test immediately, reducing their iteration cycles during development. Additionally, creating lightweight but intricate solid structures improves vehicle efficiency.

Medical Industry

The production of medical implants and surgical instruments is facilitated by metal additive manufacturing in the medical field. For instance, this technology creates patient-specific implants that exactly fit an individual’s anatomy, resulting in better outcomes and faster healing time for patients after surgery or injury due to accidents. It also allows the fabrication of delicate surgical tools, which increase accuracy during operations.

Energy Industry

Metal additive manufacturing makes energy systems components within the energy sector. It helps make such parts, which typically need high strength properties and can resist harsh environmental conditions, thus making AM a perfect method for their production requirements. Additive manufacturing enables us to design intricate geometries that improve efficiency and reliability across these systems.

Jewelry and Consumer Goods

The jewelry industry has been transformed by metal additive manufacturing, where complex designs are made with very little material wastage. This technique enables jewelers to create complicated pieces that would be impractical or impossible using traditional methods. Also, consumer goods producers employ AM to customize items with unique geometries.

Research and Development

In the research and development Field (R&D), metal additive manufacturing is necessary for quick prototyping during experimentation. Therefore, researchers can use this technological procedure to produce and test new designs briefly, which will help them innovate and discover the unknown. Rapid design iteration contributes to the fast development of new products and technologies.

Advantages of Metal Additive Manufacturing

Complex Shapes and Geometries

The ability to create complex shapes and geometries that are difficult or impossible to make using traditional methods is one of the most significant advantages of metal additive manufacturing (AM). This makes it possible to design parts with internal voids and intricate details.

Weight Reduction

Unlike other manufacturing methods, additive manufacturing allows for the creation of lightweight components without compromising on strength. The sectors that have embraced this weight reduction include automotive and aerospace, among others, where even a little weight reduction can lead to considerable savings in fuel costs.

Time and Cost Efficiency

Compared to traditional processes, metal additive manufacturing takes less time since it eliminates tooling and secondary operations, reducing production costs and lead times for producers to enter the market faster. Additionally, zero inventory reduces storage expenses.

Environmental Benefits

Compared with conventional subtractive techniques, waste generation from 3D printing is reduced since only the material required in a specific area is added. This cuts down on material costs and contributes positively towards environmental conservation. Furthermore, recycling unused powder helps promote sustainability.

Challenges of Metal Additive Manufacturing

Technical Challenges

Several technical challenges face metal additive manufacturing technologies, including achieving the desired surface finish and precision that is high enough for their intended purposes due to the requirement of additional post-processing such as machining or polishing.

Economic Constraints

High initial investments block out most businesses from setting up metal AM machines. At the same time, these machines are expensive, along with training requirements, consumables, maintenance, etc. Besides, materials used in 3D printing tend to be costly, meaning there will be high wastage rates in raw materials.

Regulatory and Standardization Issues

Metal additive manufacturing technology needs standardized testing methods or quality control guidelines, thus making quality assurance an uphill task, especially in areas like aerospace and medical devices with stringent requirements.

FAQS

What is Kinds of Powder Bed Fusion?

Selective Laser Sintering (SLS)

Selective Laser Sintering employs a laser to sinter powdered metal, fusing it to achieve a solid structure, accuracy, and efficiency being its traits.

Direct Metal Laser Sintering (DMLS)

However, DMLS is like SLA but focuses on various metals and alloys to generate prototypes and end-use products with high precision.

Selective Laser Melting (SLM)

Furthermore, SLM involves the melting of the metal powder, leading to a denser and more robust final product for applications requiring high strength and durability.

Electron Beam Melting (EBM)

This process differs from other additive manufacturing technologies. An electron beam rather than a laser is used in a vacuum to prevent oxidation, making complex parts with excellent material characteristics easy.

Conclusion

Metal additive manufacturing is a transformative technology that offers numerous benefits, including design freedom, efficiency improvements, and reduced environmental impact. With various methods available, such as powder bed fusion, directed energy deposition, and binder jetting, manufacturers can choose the best approach for their specific needs. The wide range of materials used in metal additive manufacturing allows for creating parts with diverse properties and applications.

As metal additive manufacturing continues to evolve, it is poised to revolutionize the manufacturing industry. The ability to produce complex, lightweight, and high-quality parts quickly and cost-effectively will drive its adoption across multiple sectors. While challenges remain, ongoing advancements and increasing accessibility will help overcome these obstacles, making metal additive manufacturing a cornerstone of industrial innovation in the coming years.