What is Fillet?

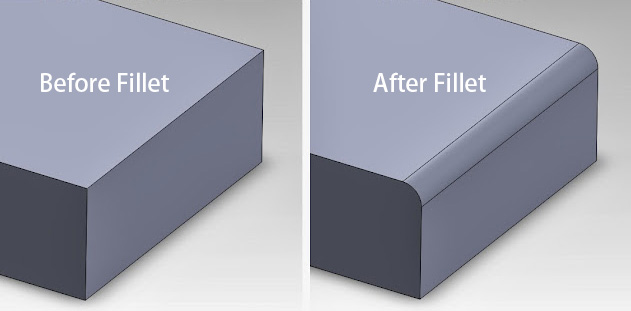

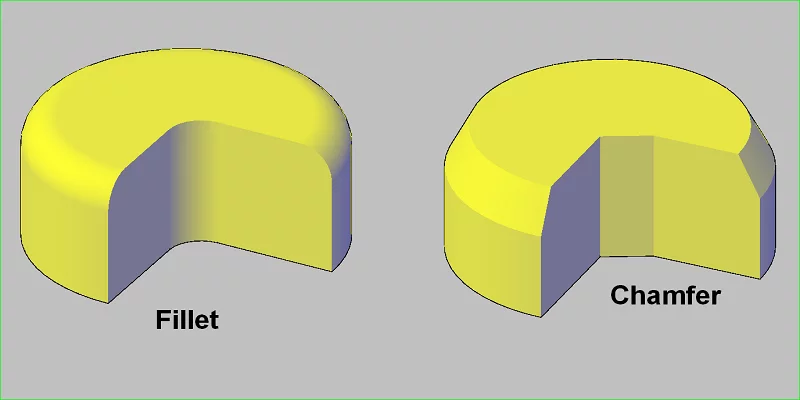

A fillet is a rounded connecting surface between two parts. Its primary purpose is to smooth out sharp corners, typically found at the intersection of two faces in machined parts and assemblies.

Interior fillets curve inward, creating a concave shape often used to enhance the flow of materials like liquids or plastics. On the other hand, exterior fillets bulge outward, forming a convex curve that strengthens the edge it adorns.

Purpose and Benefits

Stress distribution and reduction Fillets help reduce high-stress concentrations at sharp corners, which is crucial in preventing material failure under cyclic loads and enhancing the overall structural integrity of the component.

Improved load-bearing capacity and fatigue life By smoothing transitions between surfaces, fillets distribute loads more evenly across a part, increasing its load-bearing capacity and extending its fatigue life.

Aesthetic improvements Besides functional benefits, fillets can significantly improve the appearance of parts, contributing to sleeker and more integrated designs in final products.

Applications

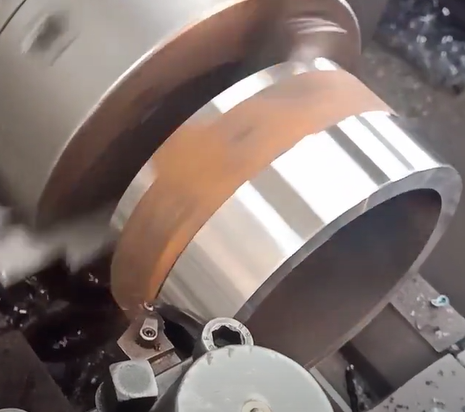

Usage in casting, machining, molding, and 3D printing Fillets are employed across various manufacturing processes to eliminate sharp edges that can cause material weakness or failure, thereby enhancing the durability and quality of the products.

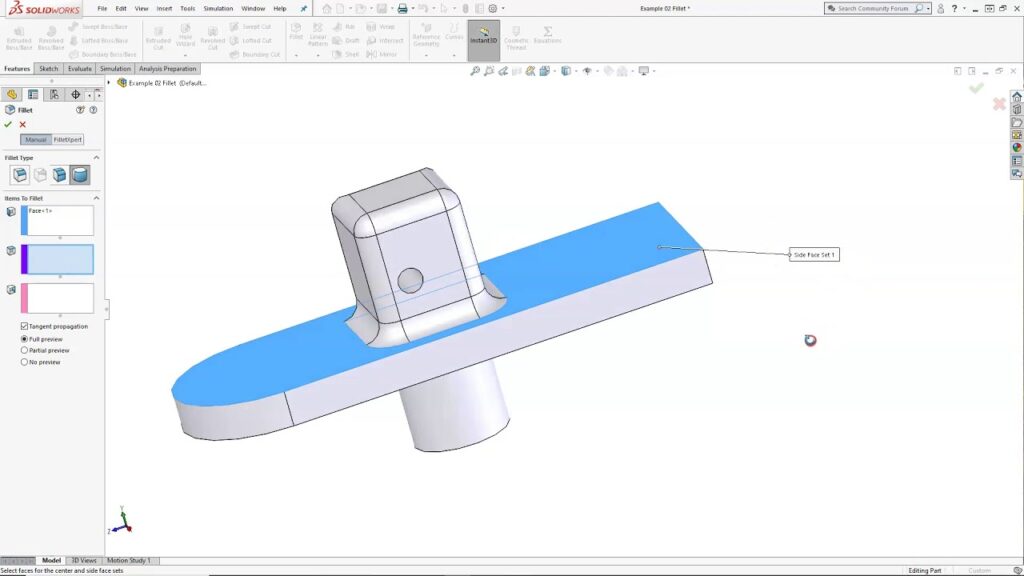

Fillets in AutoCAD® and their implementation In AutoCAD®, fillets are used to create rounded edges between two points in a drawing, simplifying the design process and ensuring that the physical properties of the fillet are maintained during manufacturing.

For example, industries and parts using fillets, such as aerospace, automotive, and consumer electronics, utilize fillets extensively to improve aerodynamics, reduce drag, and enhance the structural integrity of various components.

Design Considerations

Machining and end mill requirements Creating fillets require specific tools like end mills with appropriate radii, which must be carefully selected based on the material and desired finish of the part.

Cost implications based on radius size and edge length The cost of implementing fillets can vary significantly with the radius size and the length of the edge being rounded. Larger radii typically require more material and machining time, increasing costs.

Recommendations for efficient fillet cutting For efficient fillet cutting, it is advisable to use CNC machines with advanced programming capabilities to accurately produce the desired radius on various materials with minimal waste.

What is Chamfer?

A chamfer is an angled cut made at the intersection of two surfaces, designed to protect the edge from damage during handling, assembly, or use.

Chamfer angles are typically set at 45° or 60°, but they can vary depending on the application. These angles are selected to optimize the part’s functionality and ease of assembly.

Purpose and Benefits

Ease of assembly and part mating Chamfers often facilitate easier assembly, allowing for quicker alignment and mating of components, which is critical in high-speed production lines.

Stress reduction and deburring Chamfers help in removing burrs, which are small pieces of material that can remain attached to a part after machining. This results in smoother surfaces that reduce stress concentrations and potential points of failure.

Aesthetic contributions Chamfers contribute to the aesthetic quality of finished parts by providing a crisp, clean finish that can enhance the visual appeal of a product.

Applications

Usage in part assembly and guiding components Chamfers are crucial in assembly operations, particularly where parts must be inserted with precision. They guide components into place, reducing assembly time and potential damage during manufacture.

Chamfers in AutoCAD® and their implementation In AutoCAD®, chamfers are applied to the edges of objects to simplify drawing interpretations and ensure that the machined parts conform to geometric specifications in the technical drawings.

For example, industries and parts using chamfers are used extensively in construction, furniture making, and metal fabrication, where they enhance the functionality and appearance of structural and decorative elements.

Design Considerations

Machining simplicity and cost efficiency Chamfers are generally more straightforward and cheaper than fillets, requiring less precise tooling and typically involving fewer machining steps.

Tool requirements for creating chamfers Tools for chamfering include chamfer mills, available in various sizes and angles to match specific design requirements. Choosing the right tool is crucial for achieving the desired edge finish.

Recommendations for chamfer implementation For effective chamfer implementation, it is recommended that chamfering be integrated into the initial design stages to avoid additional machining costs and to ensure seamless assembly processes.

Comparative Analysis of Fillets and Chamfers

Functional Differences

Stress distribution capabilities Fillets distribute stresses over a larger area, making them ideal for parts subjected to cyclic loads. Chamfers, while reducing stress concentrations, are less effective in this regard.

Load-bearing suitability Fillets are better suited for load-bearing applications due to their rounded edges that distribute forces evenly, unlike chamfers, which may still concentrate stress along the cut edge.

Ease of manufacturing Chamfers are generally more accessible and faster to manufacture than fillets, requiring less precise tooling and fewer processing steps, making them a more cost-effective option in many scenarios.

Aesthetic Impact

Fillet’s contribution to smooth, seamless surfaces Fillets create a soft, flowing appearance, making them preferred for visible parts where a seamless transition between surfaces is desirable.

Chamfer’s contribution to sharp, clean edges Chamfers provides sharp, defined edges that are visually appealing in structural and architectural applications, offering a clean, precise look.

Cost and Time Efficiency

Machining time and cost differences: Fillets generally take longer to machine and may increase costs due to the complexity of the tool paths and the precision required in rounding off edges.

Tool requirements for both features Both features require specific tools; however, chamfers can often be achieved with more straightforward tools, reducing tool costs and maintenance requirements.

Safety Considerations

Fillets for improved safety and handling reduce the risk of cuts and injuries in handling by eliminating sharp corners, making them essential for consumer products where safety is a priority.

Chamfers for deburring and part mating Chamfers remove burrs that can pose risks during manufacturing and assembly, ensuring safer handling and smoother operation of moving parts.

Choosing Between Fillet and Chamfer

Factors to Consider

Part function and stress requirements The decision between using a fillet or chamfer often depends on the functional requirements of the part, including its load-bearing capacity and the distribution of stresses during use.

Aesthetic preferences Aesthetic considerations also play a crucial role, as the choice between a fillet and a chamfer can affect the final product’s visual appeal and perceived quality.

Cost and time constraints: Cost and production time are significant factors. While offering superior stress distribution, Fillets may be more expensive and time-consuming than chamfers.

Practical Scenarios

High-load parts vs. assembly parts: For high-load parts, fillets are preferable due to their ability to distribute stress and extend the part’s life evenly. Chamfers are more suited for assembly parts where ease of assembly and cost are more critical.

Applications requiring smooth finishes vs. sharp edges: Applications requiring a smooth, aesthetic finish will benefit from fillets, while those needing sharp, precise edges will find chamfers more advantageous.

Conclusion

This overview has examined the roles of fillets and chamfers in mechanical engineering, highlighting their importance in improving component performance, safety, and aesthetic qualities.

The choice between a fillet and a chamfer should be guided by considerations of functionality, cost, aesthetics, and manufacturing capabilities, ensuring that the selected feature aligns with the overall design and performance objectives.