What is 8011 aluminum?

One type of aluminum alloy that is often used is 8011 aluminum. This metal is mostly used in the packing business. This is an aluminum alloy from the 8xxx series. These alloys are very flexible and can be mixed with many other elements, such as iron, lithium, and silicon. Because it works so well and doesn’t cost too much, 8011 aluminum is often used for things like aluminum foil, cases, and boxing materials.

What is the composition of 8011 aluminum alloy?

The composition of the 8011 aluminum alloy, specifically 8011A (AlFeSi(A)), includes a range of elements that contribute to its properties.

- •Aluminum (Al): 97.5% to 99.1%

- •Iron (Fe): 0.5% to 1.0%

- •Silicon (Si): 0.4% to 0.8%

- •Manganese (Mn): up to 0.1%

- •Copper (Cu): up to 0.1%

- •Magnesium (Mg): up to 0.1%

- •Zinc (Zn): up to 0.1%

- •Titanium (Ti): up to 0.05%

- •Chromium (Cr): up to 0.1%

- •Residual Elements: collectively up to 0.15% from other unspecified elements.

How many forms of 8011 aluminum?

A lot of different businesses use 8011 aluminum foil, which is the main form it comes in. Today, 8011 aluminum comes in the following shapes and sizes.

8011 Aluminum Foil

A thin and flexible shape, this is the most popular type. With a width range of about 0.014 mm to 0.2 mm, it comes in different types. A lot of food, medicine, and industry uses put foil to use.

8011-H18 Aluminum Foil

This temper means that the foil has been partly annealed and work-hardened, which makes it stronger and last longer. This type of barrier is often used in situations that need a bigger one.

8011-O Aluminum Foil

In this form, “annealed” refers to the state of the foil, which makes it very flexible and good for deep drawing.

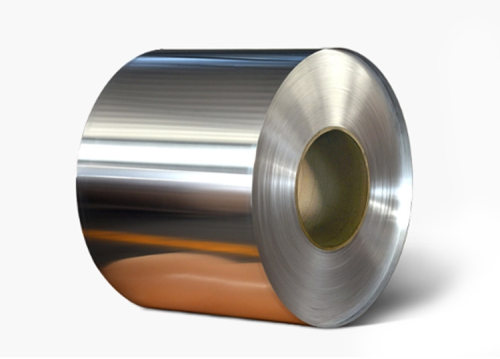

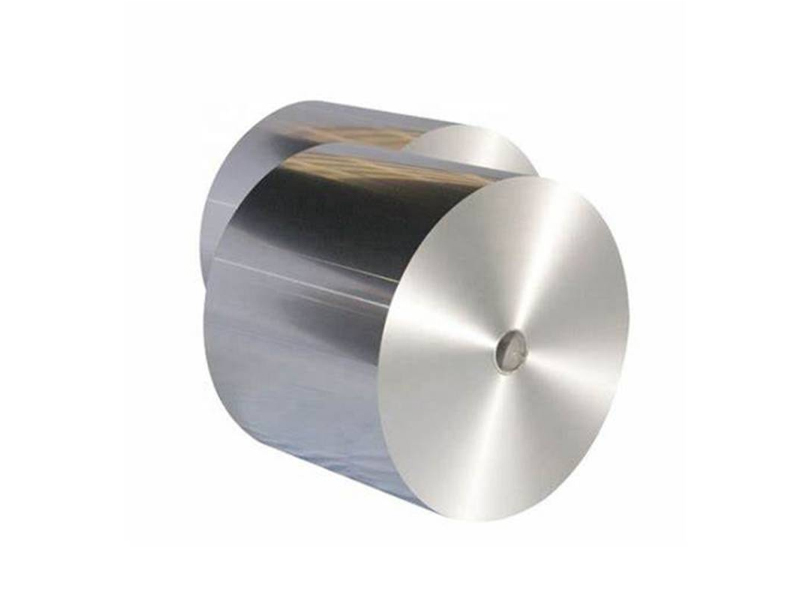

Coils and Rolls

Aluminum 8011 can also be made in coil or roll form, which makes it easier to work with during the production process. Most of the time, these coils are used to make other things, like caps or cases.

Sheet and Strip Forms

8011 aluminum is not as common as foil, but it can be made into sheets or strips for use in heat exchanges and transformer windings, among other things.

What are the applications of 8011 aluminum?

Because it is lightweight, doesn’t rust, and can be shaped easily, 8011 aluminum is a flexible alloy that is used in many fields. Its main uses are for packaging food and medicine, for industry purposes, and to make bottle caps.

Food Packaging

Several types of 8011 aluminum foil are used to package food, such as heat-sealable foil, lunch boxes, and container foil. Its great ability to keep out moisture and light helps keep food fresh and extends its shelf life.

Pharmaceutical Packaging

This alloy is widely used in pharmaceutical applications such PTP (push-through packaging), medicinal foil, capsule sheets, and cold-formed foil. The excellent strength and sealing qualities of 8011 aluminum make it perfect for safeguarding critical pharmaceuticals.

Bottle Caps

Aluminum 8011 is used to make many kinds of bottle caps, such as those for drinks, makeup, milk powder, booze, and wine. Its mechanical strength makes sure that the seal will last and work reliably.

Industrial Applications

The alloy can also be used in industry for things like generator windings, aluminum foil tape, and wire insulation. In these situations, its clean surface and flat form are helpful.

Cosmetic Packaging

Due to its good looks and durability, 8011 aluminum is often used to package cosmetics.

What are the cons and pros of 8011 aluminum?

Pros of 8011 Aluminum

- Corrosion Resistance: 8011 aluminum has good corrosion resistance, making it ideal for food and pharmaceutical packaging where cleanliness is vital.

- High Ductility: Because this alloy is very ductile, it can be readily bent and molded without breaking, making it ideal for elaborate package designs.

- Good Barrier Properties: It effectively protects packed items from moisture, light, and pathogens, guaranteeing their freshness and integrity.

- Non-Toxic: 8011 aluminum is safe to touch food, which is very important for uses in the food business.

- Heat Sealability: It means that the metal can be heat-sealed well, which makes it more useful for packaging that needs airtight locks.

- Lightweight: Even though 8011 aluminum is strong, it is also light, which helps keep shipping costs low and fuel economy high.

- Recyclable: This aluminum metal is good for the environment and can be recycled in its entirety, which is in line with sustainability goals in the packing and industrial industries.

Cons of 8011 Aluminum

- Lower Strength at Elevated Temperatures: In comparison to some other aluminum alloys, 8011 may display lower mechanical qualities when subjected to high temperatures, restricting its use in high-temperature applications.

- Limited High-Strength Applications: While it has enough strength for many applications, it may not be appropriate for applications that need extremely high strength or structural integrity under large loads.

- Potential for Galvanic Corrosion: If moisture is present in situations where it comes into touch with more noble metals, galvanic corrosion may occur, possibly jeopardizing the material’s integrity over time.

- Cost Considerations: Although aluminum is typically inexpensive for packaging applications, its price might change according to market conditions, affecting total project costs.

FAQS

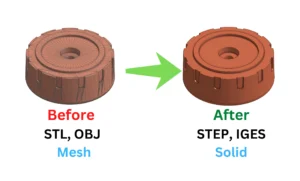

How is 8011 aluminum processed?

8011 aluminum is commonly produced into foil using twin-roll casting processes. The foil can be modified for thickness, width, and finish to fit individual needs.

Is 8011 aluminum safe for food contact?

Yes, the non-toxic, odorless, and tasteless nature of 8011 aluminum makes it suitable for food packaging.

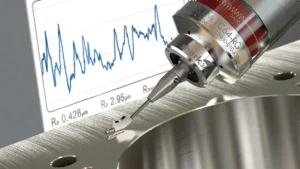

How easy is it to form 8011 aluminum?

8011 aluminum is highly formable, making it simple to mold into thin foils, sheets, or containers. It can be cold-rolled and molded without cracking, making it suitable for packaging and other flexible applications.

Can 8011 aluminum be welded?

Yes, 8011 aluminum can be welded, although the procedure may necessitate unique techniques or fillers due to its composition. It is most usually utilized in applications that do not require welding, such as foil.

Conclusion

For many businesses, especially food and drink products, 8011 aluminum is the best choice because it can be shaped easily, doesn’t rust, and is strong while being light. It can’t be used for heavy-duty tasks, but its pros usually beat its cons, making it a trusty and affordable choice.